Aluminium corner crimping machine is a special equipment for assembling

aluminum profile doors and windows. This equipment is suitable for corner code structure type aluminum doors and windows 90 degrees angle connection. Aluminium corner crimper is also known as corner squeezing machine, corner hitting machine, cornering machine. Our door and window cornering machine is manual, simple structure, easy to use, affordable price. Welcome to inquire anytime!

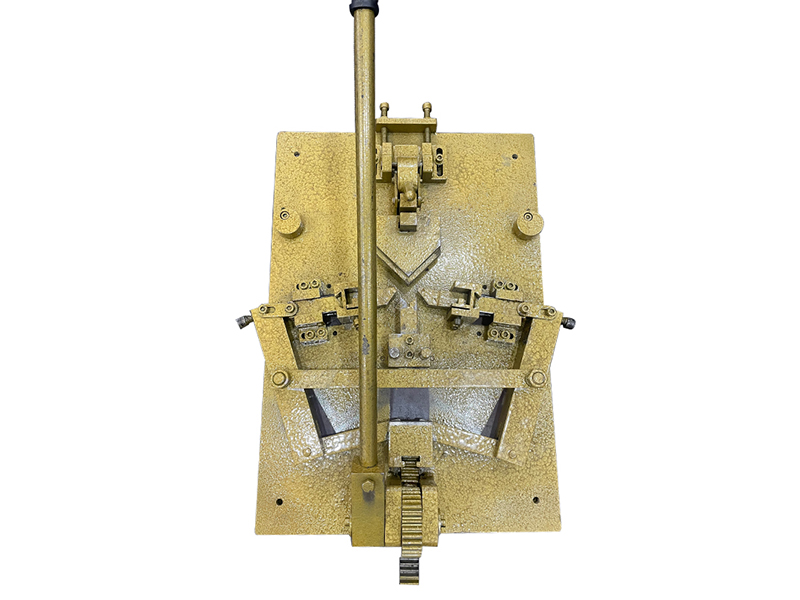

Structure of corner crimping machine for aluminium profiles

Corner crimping machine, including bracket and working table. The rear end of the workbench is set with an aluminum window limit locking mechanism. The front of the workbench is set with a manual corner-banging mechanism. The corner-impacting system includes a lever handle, a sliding block, and a connecting rod. The left and right sides of the worktable are respectively equipped with rocker arms and bumping knives. The structure adopts the linkage mechanism, the daily use and maintenance is convenient and quick, save time and labor.

Working principle of corner crimping machine

1. First of all, people use to push the handle of the door and window cornering machine, cornering slide plate forward movement.

2. At the same time, push the left and right riveting shaft.

3. Then by the punch riveting axis of the group angle knife on the doors and windows of aluminum extrusion and corner code groove buckle together.

4. Finally realize the 90 degree angle connection of aluminum door and window aluminum profiles.