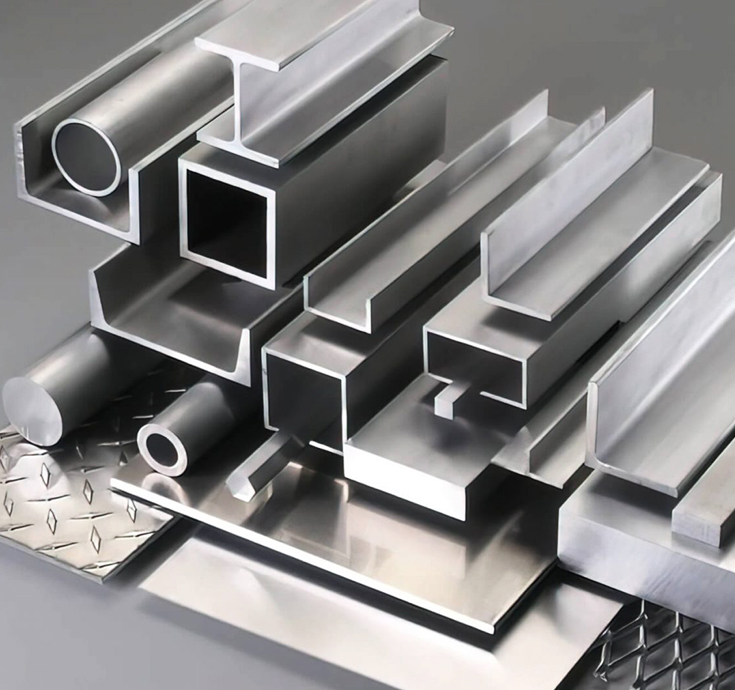

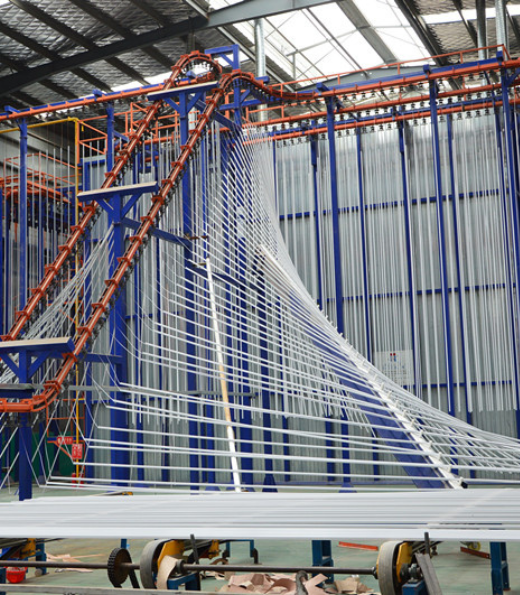

Why 1000+ Customers Trusted Retop

Retop has 20+years export experience, providing aluminum profiles for 100+ countries, large inventory, trustworthy quality

-

Free Sample2 Hours Responce

Free Sample2 Hours Responce -

Assured QualityQuality Inspection Department to control the product quality during the whole production process.

Assured QualityQuality Inspection Department to control the product quality during the whole production process. -

Competitive PriceEmploys a professional team of engineers, designers, and a sales representative

Competitive PriceEmploys a professional team of engineers, designers, and a sales representative -

Quick TurnaroundEmploys a professional team of engineers, designers, and a sales representative

Quick TurnaroundEmploys a professional team of engineers, designers, and a sales representative -

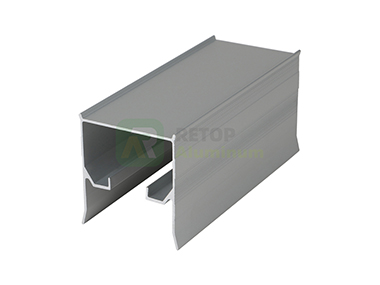

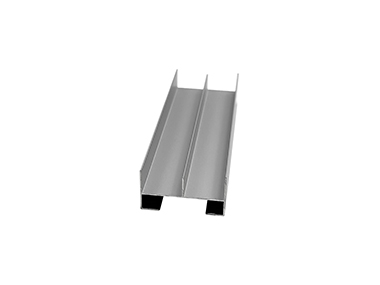

ODM & OEM OfferedIn the process of realizing the many customized needs of customers

ODM & OEM OfferedIn the process of realizing the many customized needs of customers

.png)

.png)