To provide shorter lead times and a consistent quality profile.

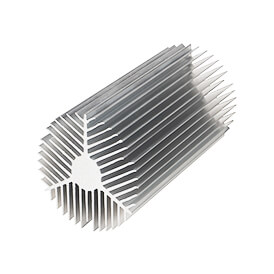

Our extruders can produce everything from the most common large extruded profiles to some of the smallest, thinnest extruded profiles in the industry.

We can squeeze out some of the strictest tolerances. Strictly follow the ISO9001 quality control system.

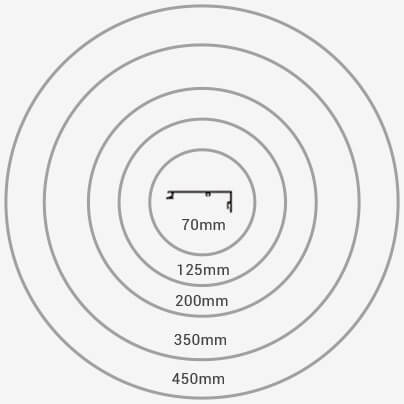

Retop has 18 extrusion lines and can produce complex extrusion parts according to customer requirements. We have state-of-the-art facilities that can produce 4,000 tons of extruded aluminum with a maximum external diameter of 450mm.

| Extruder Tonnage(T) |

Lines |

Max Circumscribed Diameter of Aluminium Profiles(mm) |

| 500 |

2 |

70 |

| 580 |

5 |

85 |

| 920 |

5 |

125 |

| 1460 |

2 |

157 |

| 1800 |

2 |

200 |

| 2600 |

1 |

260 |

| 3600 |

1 |

350 |

| 4000 |

1 |

450 |