The raw material of aluminum batten is aluminum alloy.

Length of aluminum roof battens

The length of aluminum battens is not fixed, but customized according to the specific needs and specifications of the application. The common length standards for aluminum slats are 2000mm, 2500mm, 3000mm, 4000mm, 5000mm, 6000mm, and so on. However, it is important to note that the length requirements for aluminum panels will vary for different applications and needs.

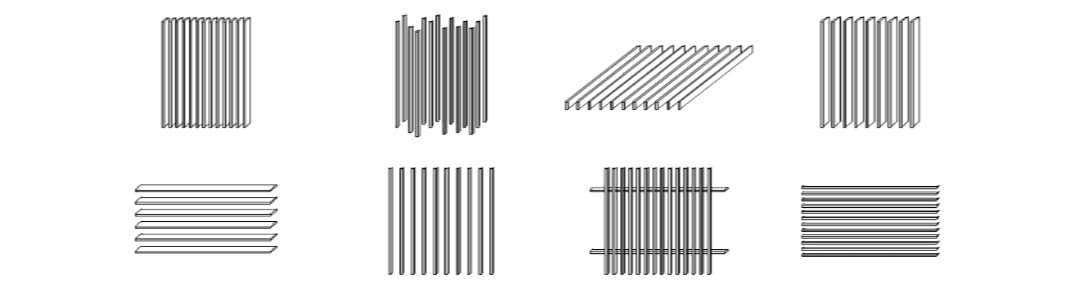

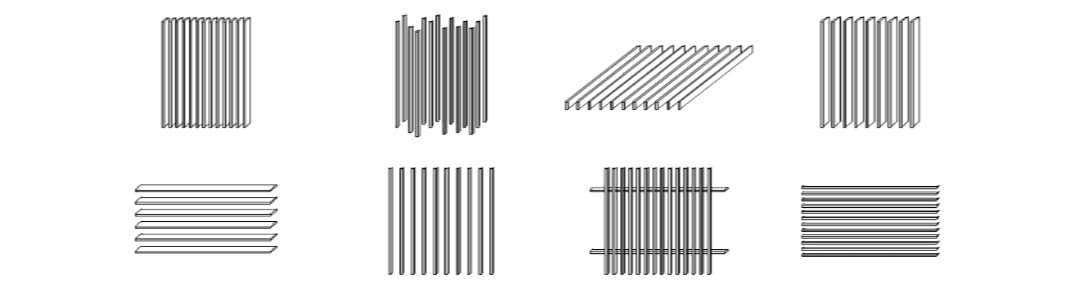

Different styles of aluminium batten

The styles of aluminum sheet can be various.

1. A common style of aluminum sheet is the long strip. This shape of aluminum sheet is generally used on the exterior of a building. We call these aluminum sheets vertical aluminum battens or aluminum batten screening.

2. It can also be shaped, such as: wavy, U-shaped, round, J-shaped, V-shaped and so on. These shapes of aluminum sheets are generally used in the interior of buildings. Ralto can provide various shapes of aluminum sheets.

3. Aluminum slats can be pieced together and combined into different styles of aluminium battens styles. The exact presentation varies according to the customer's design.

How to maintain vertical aluminium battens?

How to maintain vertical aluminium battens?

The maintenance of aluminum sheet is very simple, the following are the suggestions provided by Raflatac about the maintenance of aluminum sheet:

1. Regular cleaning: Use mild soapy water or special aluminum cleaner to clean the surface of aluminum sheet. Avoid using cleaners containing acidic, alkaline or abrasive agents to avoid damage to aluminum. After cleaning, dry the aluminum surface with a clean soft cloth.

2. Avoid contact with salt water: Aluminum is susceptible to corrosion by salt water, so try to avoid aluminum sheet contact with seawater, salt lake water, and other substances containing high salt content.

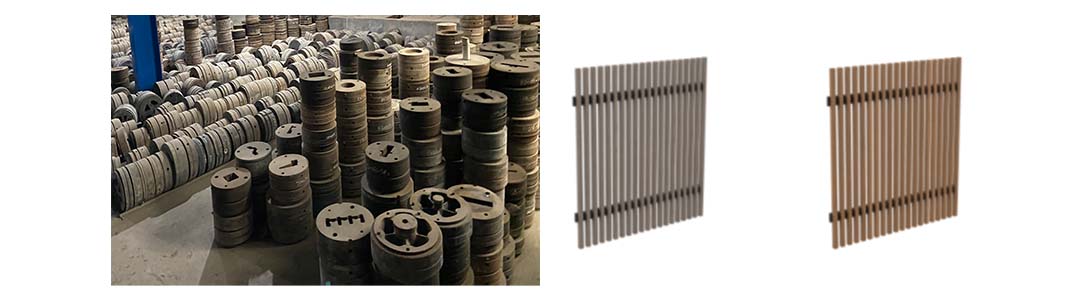

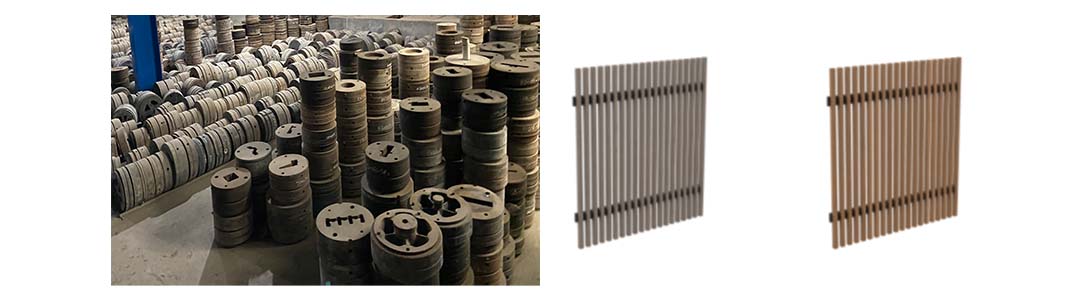

Customized aluminium ceiling battens Retop provide

Customized aluminium ceiling battens Retop provide

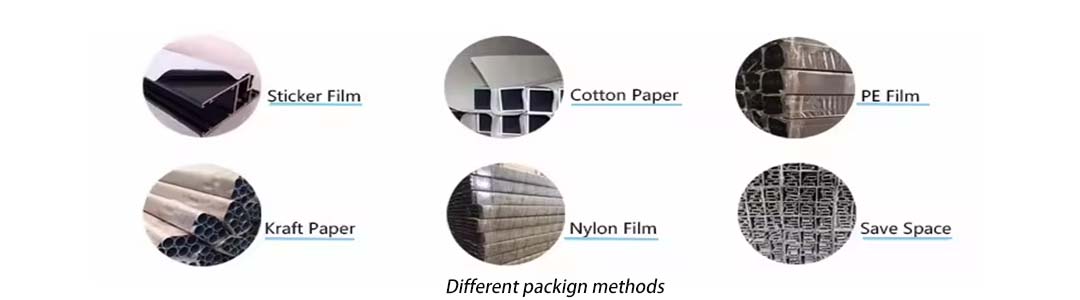

There are many aspects of customized aluminum sheet services that Retop can provide. It mainly includes customized service of mold opening, material selection and alloy formula, surface treatment, color selection, deep processing treatment (cutting, drilling, tapping, etc.), packaging and transportation, etc.

.jpg)