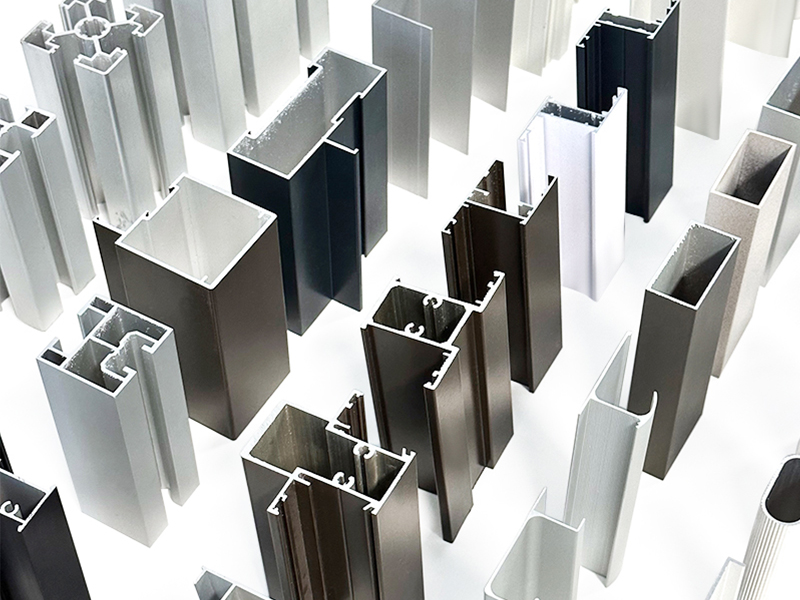

Aluminium profiles deep processing facilitates the production of high-precision and complex aluminum profile products. The added value of the processed

aluminum alloy is higher, which is in line with the customer's usage scenario. It can also meet the special requirements of different industries. In general, the aluminum profiles just extruded under can not be used directly. It needs to be further processed later to be applied.

For example, using surface treatment to make aluminum profiles more beautiful, cutting and drilling to make aluminum extrusions have uniform specifications. Retop provides a variety of aluminum profiles deep processing technology, professional aluminum profiles CNC machining service so that your aluminum profiles can have accurate dimensions and functions. We have strong aluminium profiles deep processing capabilities to help you process aluminum profiles in large quantities.

What is aluminium profiles deep processing?

Aluminium profiles deep processing refers to a series of precision machining treatments for aluminum material. Deep machining results in an aluminum product that meets specific design, functionality, or application requirements. Typical deep machining operations include cutting, bending, stamping, welding, and CNC machining.

A quality deep processing of aluminium profile can help customers achieve specific shapes and precision aluminum profiles. Retop can provide all deep machining services in the market. We have customers in many countries around the world and most of them are satisfied with our deep processing aluminium extrusion profile services.

Normal sequence of aluminium profiles deep processing

If you need aluminium profiles deep processing service, our normal service flow is as follows:

1.Determine the drawing and design

Before deep machining, we need to determine the correct aluminum extrusions design style, color, price, etc. with the customer first.

2. Prepare the required molds and materials

Customers need to pay the relevant fees first, then we will prepare the relevant materials and technical services. For example, machining, heat treatment, surface treatment, CNC deep processing and so on.

3.Deep machining operation

We will use advanced CNC machine tools to carry out deep machining operations, including cutting, milling, bending, uncoiling, drilling and so on.

4.Inspection

After the aluminium profiles deep machining work is completed, we will check all the products. Retop will make sure that each processed product meets the specifications and standards. We will also make the final product available for your inspection.

5.Packaging

We have a variety of packaging forms. We will take the appropriate packaging according to the specific product, for example, plastic packaging, shrink wrap packaging, internal paper and external plastic packaging.

Specific aluminium extrusion for deep processing operations

1.Forming

We use special molding machines to shape aluminum profiles into suitable shapes. For example, we will handle longer aluminum profiles using hydraulic presses and bending machines to bend the aluminum sections according to your requirements.

2.Sawing

We will use saws to cut the aluminum extrusions into the lengths required by our customers. We also have an automatic sawing machine to produce aluminum profiles with smaller length tolerances.

3.CNC Milling

In order to be able to process complex aluminum profile parts, we have high speed 3-axis, 4-axis and 5-axis milling machines. In addition to this, we have CNC vacuum milling machines as well as horizontal and vertical CNC lathes. These machines help us to be able to machine different depths of cuts and drilled holes.

4. Punching

We use automatic punching machines to process aluminum sections into lightweight architectural products for mass production. In this way, you get aluminum products with the desired grooves.

5.Welding

For the aluminium profiles deep processing by welding, we use a 10-axis robotic welding system that allows us to further process aluminum profiles. During the welding process we use pulse and double pulse processes.

6. Joining and bonding

We use fully automated processing technology to bond various aluminum profiles components. We combine bonding systems with robots to achieve the ideal production solution while maintaining the same high quality.

What are the steps of deep processing of aluminum profiles?

Aluminum profiles are not used directly after production, but are generally subjected to deep processing. The general process of deep processing is as follows:

1. Sawing: The length and length of the freshly produced aluminum profiles generally do not meet the transportation and use standards. Therefore, it needs to be sawed. We will use CNC sawing machine to cut the size of the aluminum profile and the angle of the end. Retop's cutting precision can reach 0.1mm, the cut is flat and smooth, no burr.

2. Fixed jigs and fixtures: Before starting the aluminium profiles deep processing, it is crucial to fix the aluminum profile workpiece stably on the processing machine. This will prevent errors caused by positional deviation.

3. Adjust the machining center data: Program the machining center according to the user's needs, including the machining steps of the CNC aluminum profile CNC machining center, such as milling flat surfaces, milling slots and punching holes.

4. Cleaning: As lubricants will be used in the aluminium profiles deep processing, oil may remain on the aluminum profiles, so they need to be cleaned and dried after cleaning.

5. Final packaging: common CNC machining of aluminum profiles packaging methods include the use of non-woven fabric separation and the use of pearl cotton packaging.