The application of general aluminium profile involves a number of fields, among which the most frequently applied fields are the following:

1. Construction field: Standard aluminum profiles are most frequently used in the construction field. For example, they are used for door and window frames, curtain track systems, curtain wall systems, staircase handrails, fences, columns, and other building structure components.

2. Transportation: Basic aluminum profiles are also used in body structures, interiors and other parts of vehicles such as cars, trains and airplanes.

3. Furniture decoration: Used in furniture manufacturing, such as closet, display racks, furniture frames, etc.

4. Machinery manufacturing: The ordinary aluminium profile in the manufacture of mechanical equipment, frames, brackets, drive systems, etc.

5. Solar industry: It is also used in the manufacture of solar energy stents, frames, photovoltaic cell module support structure.

6. Sports equipment: Round tube basic aluminum profile is mainly used in the manufacture of bicycles, golf clubs, hiking poles and other sports equipment.

Advantages of ordinary aluminium profile

1. Simple structure, can be applied in a wider range. The structure of basic aluminum profile allows it to be applied in many other fields. It can also be connected with many other accessories and objects.

2. Customizable. A variety of different sizes of basic aluminum profiles can be adapted to a variety of application scenarios. We support the customization of various aluminum profiles, in addition to the basic aluminum profiles, there are also aluminum profiles for doors and windows,

aluminum profiles for cabinets, aluminum profiles for T-slots, etc. We can customize the aluminum profiles according to the customer's specific use. We will recommend the right size and style according to the customer's specific use.

3. Low production cost of basic aluminum profiles. The structure of basic aluminum profiles is simple, and most factories have these basic molds. It can be produced in large scale. Therefore, the cost of making these basic aluminum profiles in factories will be lower. Customers will also save more cost.

4. Simple production process. Due to the simple structure of the basic aluminum profiles, these aluminum profiles are generally material and do not require surface treatment and so on. Therefore the production process is also a bit simpler.

5. Sturdy and stable: Although the structure of the basic aluminum profile is simple, but the amount of material, the structure is solid and less prone to problems.

6. Recycling: Basic aluminum profiles have a higher recycling rate. Basic aluminum profiles generally do not go through the spraying, anodic oxidation of the surface treatment, so the recycling of aluminum alloy content of impurities is less, recycling rate is higher.

7. Good conductor: Aluminum material has good electrical conductivity. In real life, aluminum is often used as an electrical conductor, such as power transmission lines, cables, electrical equipment, conductive parts. Therefore, aluminum will be widely used in the field of electronics and electrical engineering.

What is the price of standard aluminium profile?

The price of standard aluminium profile is not fixed, it varies with different factors.

1. International aluminum prices. The rise or fall of raw materials will directly affect the price of aluminum profiles. Customers can check what the international aluminum price is before buying aluminum profiles.

2. The supply and demand of standard aluminum profiles: The price of aluminum profiles will fall if there is an oversupply of aluminum profiles, and the price of aluminum profiles will rise if there is an undersupply of aluminum profiles.

3. The specifications of the ordinary aluminum profiles: If you need the basic aluminum profiles with larger specifications, the price will be higher. For example, the length and width of the basic aluminum profile, wall thickness and so on.

4. The quantity of standard aluminum profiles you need: In general, the more quantity you buy, the lower the price offered by the aluminum profile supplier will be. We are the preferred manufacturer for many customers because we produce aluminum profiles with reasonable price and good quality at low price.

5. Raw materials for basic aluminum profiles: High-quality raw materials usually have better corrosion resistance, strength and toughness. Such aluminum alloy will have a longer service life and better stability. Therefore, high quality raw materials will cost more.

How do I choose an aluminum profile?

Choosing the right aluminum profile generally involves a process of defining the requirements, determining the specifications, determining the quantity and choosing the supplier.

1. Define the application requirements: First of all, determine what you need the aluminum profile to be used for. This is because different types of aluminum profiles may be needed for different applications.

2. Selection of aluminum alloy: Aluminum profiles are available in different alloys, all of which have different characteristics. For example, 6000 series, 7000 series, 8000 series and so on. They have different characteristics and different applications. We need to choose the corresponding aluminum alloy series according to the needs.

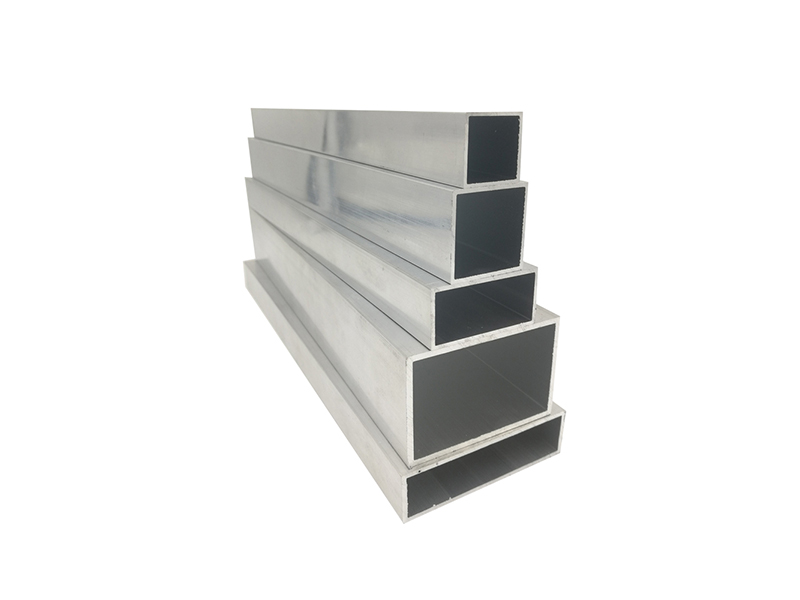

3. Determine the specifications of aluminum profiles: These specifications generally include the shape, length, width, height, thickness, etc. of the aluminum profiles. Some may also need to customize the special structure of the aluminum profile.

4. Whether surface treatment is required: Some aluminum profiles must be surface treated, because such aluminum profiles not only have a functional role but also have a decorative function. According to the demand to determine the surface treatment is anodic oxidation, electrophoretic coating or powder coating.

5. The number of

aluminum alloy: The number of aluminum profiles purchased will affect the purchase cost. We can compare several aluminum profile suppliers and, within our budget, choose the most cost-effective aluminum alloy.

6. Quality supplier: We have to choose a quality aluminum profile supplier. We can check the supplier's history, customer reviews and product quality. A good supplier can guarantee to have high quality products and excellent after-sales service.

Customized service of standard aluminium extrusions-from Retop

1. Shape and size: We will customize the shape and size of special aluminum profiles according to customer's design drawings or specific requirements. To meet the needs of specific projects.

2. Surface treatment: We Retop provide different surface treatment, such as anodic oxidation, powder coating, wood grain transfer printing and so on. Customers can also specify the color and style.

3. Accessory processing: We also provide deep processing services, such as cutting, drilling, stamping, etc., to suit specific assembly needs.

4. Material selection: According to customer's requirements, Retop will provide different types of alloy material selection to meet the needs of special environments and applications.

5. Quantity and delivery: We can provide flexible production schedule according to customer's order quantity and time requirement to ensure on-time delivery.