Aluminum profiles, a kind of profiles made of aluminum as the main material, are widely used in many fields such as construction, transportation, electronics and so on because of its light weight, high strength, corrosion resistance and other characteristics. With the development of science and technology, the application scope of aluminum profiles is expanding, and the market demand continues to grow. In this paper, we will analyze the basic concept of aluminum profiles, production process, application areas, development trends and other aspects in detail.

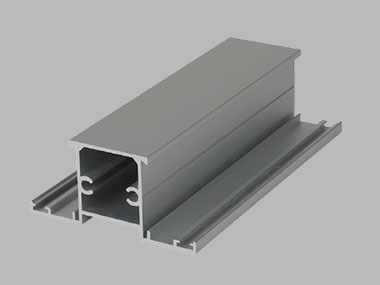

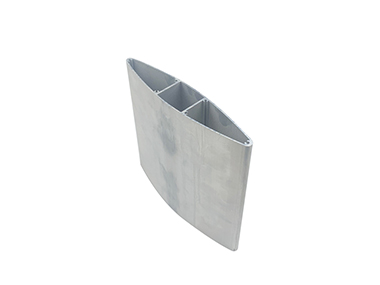

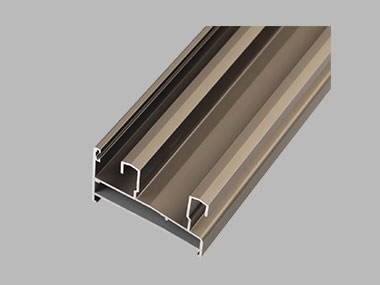

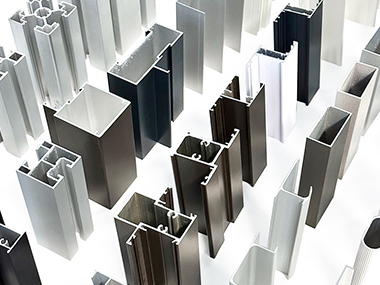

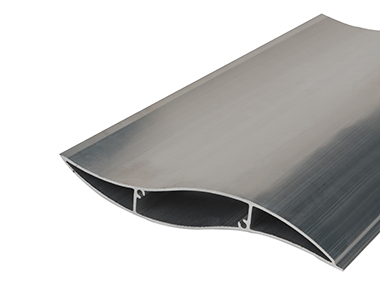

aluminum profiles refers to a series of profiles manufactured through the aluminum extrusion process, which is characterized by light weight but high strength, good plasticity and corrosion resistance. There are many kinds of aluminum profiles, the common ones are aluminum alloy profiles, aluminum frame profiles, aluminum tubes and so on. According to different application requirements, the size, shape and surface treatment process of aluminum profiles will be different.

The production process of aluminum profiles mainly includes the melting of aluminum ingots, extrusion of aluminum ingots, cutting and surface treatment of profiles and other aspects.

1. melting ingot: aluminum ingot is the raw material for aluminum profile production, the producer will be aluminum alloy raw material for melting, to ensure that the composition of the aluminum liquid is uniform, to meet the production requirements. 2. extrusion: aluminum liquid is the raw material for aluminum profile production.

2. Extrusion: After the aluminum liquid is heated to a suitable temperature, it is pressed into the die through an extruder, and aluminum profiles of different shapes are formed through this process. This process has a crucial impact on the shape and dimensional accuracy of aluminum profiles.

3. Cooling and Cutting: After the extruded aluminum profile is cooled, it is cut, and the precision of cutting will directly affect the difficulty and cost of subsequent processing.

4. surface treatment: in order to improve the corrosion resistance and aesthetics of aluminum profiles, the surface treatment process is indispensable. Common surface treatment methods include anodic oxidation, electrophoretic coating, spraying, etc. Different treatment methods make aluminum profiles different in appearance and performance.

aluminum profiles widely used in a number of industries play an important role. The following are examples of the application of aluminum profiles in major industries:

1. Construction industry: Aluminum profiles are used for doors, windows, curtain walls, parapets and other building materials, and their excellent corrosion resistance can effectively extend the service life. At the same time, the color and design style of aluminum profiles can be perfectly integrated with the architectural style.

2. Transportation: Aluminum profiles are widely used in the fields of automobile manufacturing, ship and railroad transportation because of their light weight. Lightweight aluminum profiles can reduce the weight of transportation vehicles, improve energy efficiency and reduce fuel consumption.

3. electronics industry: aluminum profiles are increasingly common in the application of electronic equipment shell, because of its good heat dissipation performance, can effectively protect the electronic components, and extend the service life of the product.

4. machinery manufacturing: aluminum profiles are also widely used in mechanical structural parts, because of its high strength, easy processing and other characteristics, become an important material in the field of machinery manufacturing.

With the global emphasis on environmental protection and sustainable development, the aluminum profile industry is also facing new challenges and opportunities.

1. Development of Green Aluminum: With the concept of sustainable development taking root in people's minds, more and more manufacturers are exploring green aluminum production processes. The usage rate of recycled aluminum is increasing year by year, and the benefits of aluminum recycling are remarkable. In the future, aluminum profiles made from recycled aluminum will become mainstream.

2. The introduction of intelligent manufacturing: with the rise of Industry 4.0 and intelligent manufacturing, aluminum profile production will also gradually develop in the direction of intelligence and automation. Through the Internet of Things, big data and other technologies to improve production efficiency and product quality will become the new direction of the industry.

3. Diversified product demand: the market demand for aluminum profiles is increasingly diversified and personalized, manufacturers need to produce a variety of specifications and shapes of aluminum profiles according to the different needs of customers, to enhance the market share of products.

4. Driven by technological innovation: In the context of new material research and development and the continuous upgrading of processing technology, the performance of aluminum profiles will continue to improve. For example, the emergence of new materials such as enhanced aluminum alloy and high-temperature-resistant aluminum alloy will push aluminum profiles toward the goal of higher performance.

aluminum profiles have become an indispensable and important material in modern industry due to their excellent characteristics. In the future, with the continuous progress of science and technology and changes in market demand, the aluminum profile industry will usher in new development opportunities. The versatility and developable potential of aluminum profiles will surely play a more important role in more fields.