Equipment advantage

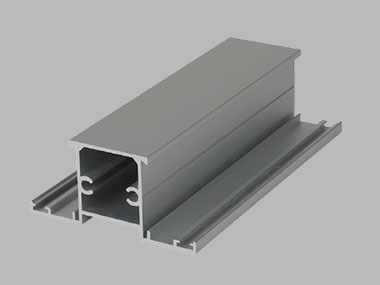

We are a comprehensive production enterprise integrating

aluminum profile production and aluminum profile deep processing, providing one-stop service from aluminum ingots to finished products. More than 100 sets of imported processing equipment, from mold manufacturing, aluminum rod casting, profile extrusion, surface treatment (oxidation, electrophoresis, spraying), heat treatment, CNC machining, welding, bending, bending, stamping, skin stretching, all can be completed independently in the same factory area of our company to meet customers' various delivery requirements for products from profile delivery to component delivery.

Process advantage

Generally,

aluminum alloy profiles will have performance changes after being extruded for 12 hours, which has an adverse effect on the processing of car body and component profiles, such as drawing, bending, and stamping. Our company can process the aluminum profiles in T4 state within 12 hours after extrusion of the car body and component profiles, without causing changes in the organization and properties, and can return to the workshop after completion. Aging treatment. No annealing is required to avoid the negative impact of natural aging on the performance of the material processing technology, ensuring that the properties and dimensions will not change with the change of tension and bending. The technological process and processing time are shortened, the product performance and yield are improved, the product quality is guaranteed, and the production cost is reduced.

Technical advantages

The company adopts a two-line parallel research and development model, sets up a special department internally to track cutting-edge technologies, and externally sets up an industry-university-research base. After years of research and development accumulation, the company has gradually mastered a number of advanced technologies.