In recent years there has been an increased focus on environmental sustainability and an increased focus on fuel efficiency, however, aluminum extrusions have become a game changer in the transportation industry. Known for its lightweight and recyclable properties, aluminum has become the preferred choice of manufacturers looking for sustainable solutions. This trend is driving dramatic changes in the transportation industry.

The demand for lightweight materials in the transportation sector is growing strongly. As governments and consumers become more aware of the environmental impact of carbon emissions, industries are looking for better solutions. Because of its many favorable properties, aluminum plays an important role in the production of automobiles, aircraft and other vehicles.

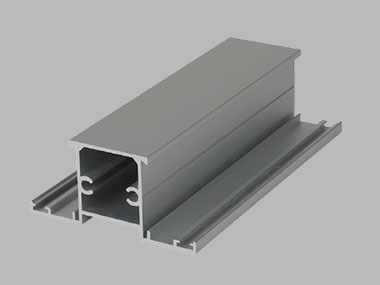

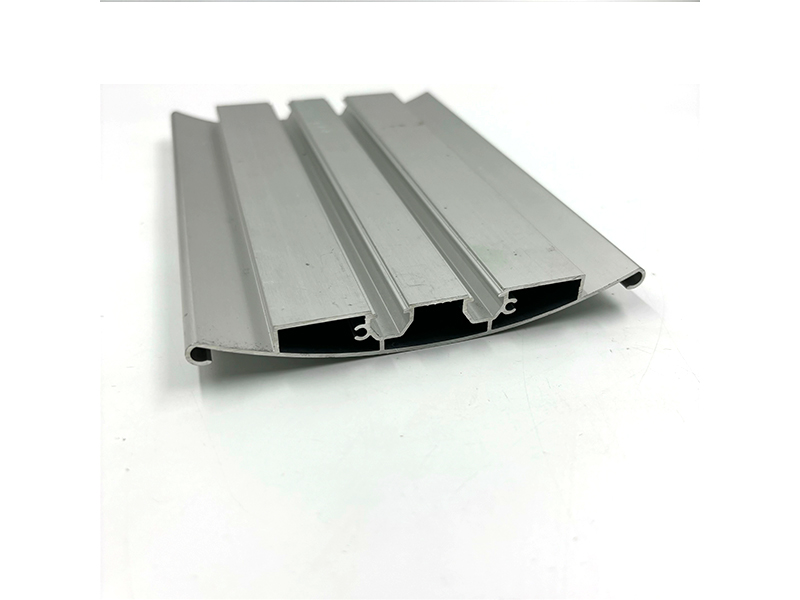

Due to the coexistence of solid and liquid, aluminum profiles can be extruded into various shapes of aluminum profiles. This flexibility allows designers to open up more of the aerodynamic structure, reducing drag and optimizing fuel efficiency. In addition, the corrosion resistance of aluminum ensures the longevity of components, reduces maintenance costs and increases sustainability.

Automakers have embraced aluminum extrusion to create lighter, more fuel-efficient vehicles. Reduce vehicle weight by replacing traditional steel components with aluminum components, improving energy efficiency and reducing greenhouse gas emissions. Additionally, aluminum's recyclability allows for a closed-loop recycling process, ensuring end-of-life vehicles can be reused efficiently and with reduced environmental impact.

The aerospace industry also recognizes the benefits of aluminum extrusion. Lightweight aircraft components made of aluminum alloys help save fuel during flight, making air travel more sustainable. In addition, the extrusion process allows the production of complex and high-strength structures, providing greater safety and durability for aircraft and helicopters.

In addition to automotive and aerospace applications, aluminum extrusions find their way into various areas of the transportation industry. Railroads are using aluminum extrusions to create lightweight yet strong train bodies, reducing energy consumption and improving performance. The shipping industry is also starting to incorporate aluminum extrusions into ship structures to reduce weight and improve fuel efficiency at sea.

In conclusion, the aluminum extrusion industry is reshaping the transportation industry by providing lightweight and sustainable solutions. With its exceptional properties and recyclability, aluminum is driving innovation in the automotive, aviation, rail and marine industries. As the world moves towards a greener future, aluminum extrusions are expected to play a key role in reducing carbon emissions, improving fuel efficiency and ensuring a sustainable and environmentally friendly transportation landscape.