In the development of the modern medical industry, aluminum profiles have become a valuable material for the medical industry. With its good properties and numerous advantages, aluminum extrusions pave the way for innovation and advancement in the medical industry.

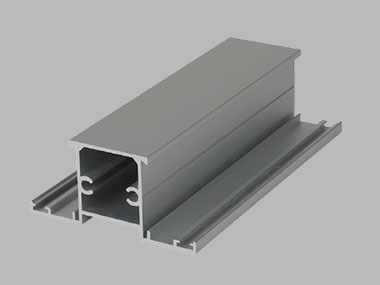

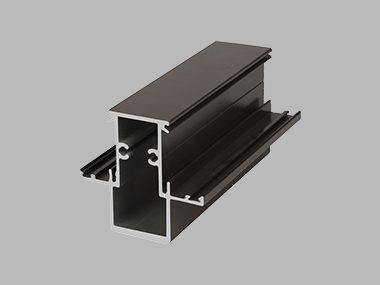

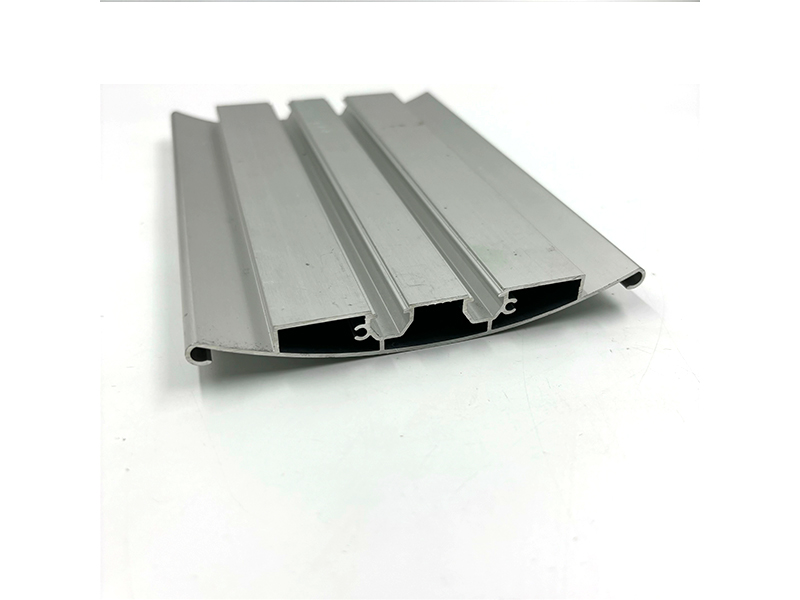

Known for its lightness, durability and corrosion resistance, aluminum has long been used in industries such as aerospace and construction. As the medical industry advances, its potential in the medical field is recognized by everyone. Aluminum's malleability allows for the creation of complex shapes and structures, making it an ideal material for medical devices, devices and components.

Aluminum profiles are mainly used in the manufacture of medical equipment in the medical industry. From surgical instruments to diagnostic equipment, aluminum has many advantages over traditional materials. Its lightweight nature relieves healthcare professionals of stress during lengthy procedures, enhancing ergonomics and minimizing staff fatigue. In addition, it is important to note that the non-magnetic properties of aluminum are beneficial for medical devices that need to be compatible with magnetic resonance imaging (MRI) technology.

In addition, due to the easy extrudability of aluminum profiles, aluminum profiles are widely used in the production of medical accessories. Hospital beds, stretchers and wheelchairs require a certain level of strength, stability and corrosion resistance so aluminum profiles just solve this problem. Aluminum is able to withstand stringent sterilization procedures and maintain clean sanitation, as infection control is critical in healthcare settings.

Another valuable advancement is that aluminum profiles can be used in the development of prosthetics for patients and surgical equipment. Because of its lightweight and strong properties, aluminum can be the best choice for constructing prosthetics and braces. Patients can experience a high level of comfort when using these devices, improving their quality of life in the hospital.

The use of aluminum extrusions in the medical industry not only benefits patients and healthcare professionals, but also has environmental advantages. Aluminum is a highly recyclable material that complies with the healthcare industry's sustainability initiatives. Its recyclability reduces waste, conserves resources and facilitates greener and greener medical manufacturing methods

The huge use of aluminum profiles in the medical industry once again reflects the wide application of aluminum profiles. Aluminum profiles have played a huge role in all aspects of society with their own good characteristics.