The quality of aluminium door and window profile is related to its beauty, service life, maintenance costs and other aspects. Therefore, many consumers will pay much attention to judge the quality of aluminum profiles for windows and doors before purchasing. There are many ways to judge the quality of aluminium extrusion profile for window and doors. We start from different perspectives so that buyers with different needs can purchase high-quality aluminum products through their own judgment. The following is a variety of judgment methods summarized by Retop. Hope it can help you.

Observing the aluminium door and window profile surface

By observing the surface is the most simple and direct way to judge.

1. The surface of aluminium door and window profile should not be obvious damage. For example: traces of abrasion scratches.

2. The surface of aluminium door window profiles should be smooth and bright, and there should be no depressions or bumps.

3. There should be no aluminum chips, burrs, oil spots or other stains on the surface of aluminum profiles for doors and windows. At the same time, there should be no spillage of adhesive at the assembly connection.

4. There should

be no obvious color difference on the same part of the aluminium profile doors and windows.

5. Identification of signs. Formal aluminum manufacturers, aluminum alloy products will have product markings. The content of the marking generally have: manufacturing plant name or trademark, product name, product model, manufacturing date, manufacturing number and so on. The specific content will vary with different manufacturers.

Determine the aluminium door window profiles quality by testing

Determine the aluminium door window profiles quality by testing

Using an instrument to test the quality of aluminium door and window profile is a more accurate method of testing. This can determine if the aluminum profiles are truly quality aluminum profiles for windows and doors. If you want this quality information before you buy, tell the aluminum profile manufacturer what you need. Here are the main testing aspects:

1. Quality testing of raw materials

The raw material of aluminum profiles for doors and windows is usually 6063 aluminum alloy. 6063 aluminum alloy contains high quality pure aluminum and

magnesium, silicon metal elements. High purity aluminum raw materials and the right proportion of precious metal elements together constitute a high-quality 6063 aluminum profiles for doors and windows.

The prepared raw material is melted in an aluminum melting furnace, cooled, and then cast into ingots or bars. If the manufacturing process is not well ventilated, air bubbles can form in the aluminum profiles causing defects. If the raw materials of aluminum profiles for doors and windows are made of 6063 aluminum profiles in accordance with international standards, then it means that the quality of raw materials is good.

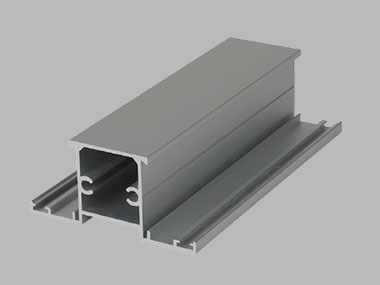

2. Aluminum profile wall thickness test

In reality, the deformation of aluminium door and window profile is largely due to its wall thickness is not up to standard. But there is no uniform thickness standard for wall thickness, generally with the use of the profile scene and the specific needs of customers to determine. But too thin wall thickness is certainly a problem. Aluminium window and door glazing profiles, including frames, slides and other stressed components, the minimum wall thickness of these stressed components should be not less than 1.4 mm. Outside the door is not less than 2.0 mm. test wall thickness method is to use vernier calipers on aluminum profiles for random sampling inspection on site.

3. Aluminum profile strength test

The strength of high-quality aluminium window and door glazing profiles should be able to withstand a certain degree of dynamic and static pressure tests. This generally requires professional instruments for testing. The tested data should be in line with national and industry standards. Qualified aluminium door and window profile will have good safety and stability in actual use.

Ways of determining aluminium profile doors and windows quality with different surface treatments

Ways of determining aluminium profile doors and windows quality with different surface treatments

1. Anodized aluminium door and window profile

Use a smooth hard object to gently scratch the surface of aluminium extrusion profile for window and doors to see whether the surface of the profile will leave white traces. At the same time, whether the white marks can be wiped off by hand. If it can not be wiped off that the anodic oxidation film is still there. Conversely, the anodic oxidation film of the aluminum profile is too thin and too poor. The average film thickness of anodized

aluminum profiles for doors and windows should be at least 15um, and the thickness of anodized film for doors and windows produced by Retop is more than 15um.

2. Powder coated aluminium window door profiles

Powder coating surface should be delicate, full, transparent, three-dimensional sense of strong, and can maintain the relative luster for a long time. The thickness of powder coating is at least 40um. poor quality powder coating has a dull appearance and poor three-dimensional effect. Then there are phenomena such as loss of light and paint peeling after using for some time. In addition to this, there is almost no orange peel phenomenon in high-quality sprayed profiles. Therefore, whether the powder coated aluminum profiles for doors and windows are of high quality can be judged by carefully viewing the surface.

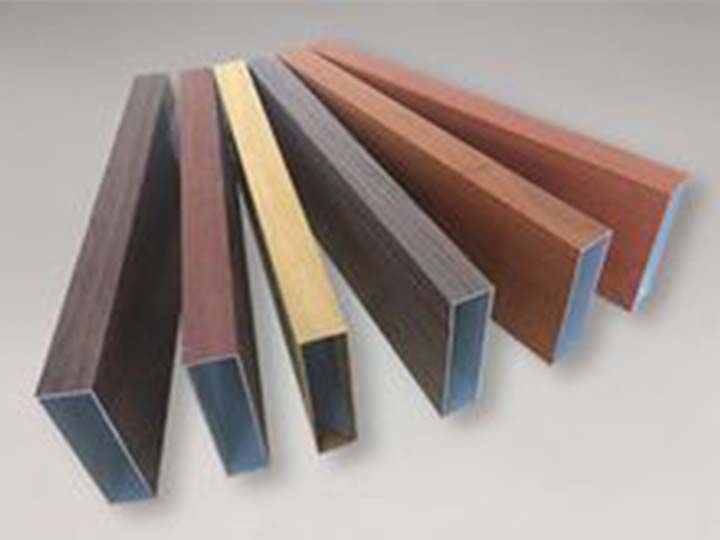

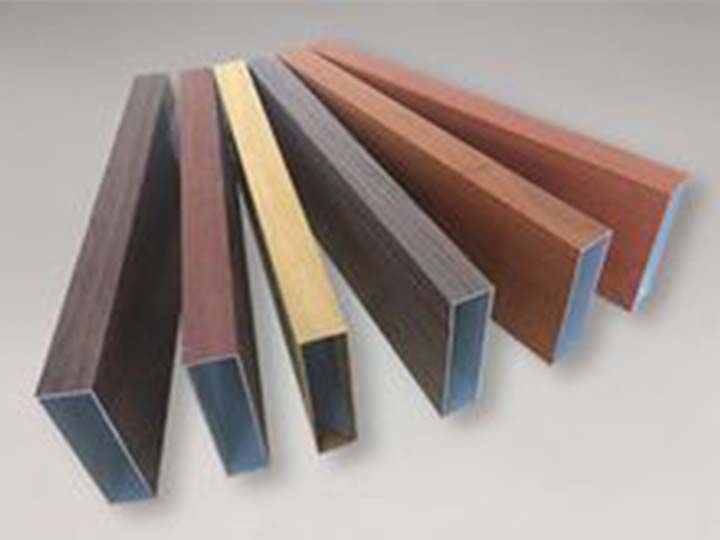

3. Wood grain aluminium door and window profile

When evaluating wood grain finishes, the primary concern is the smoothness and flatness of the surface. The finish should be smooth and free of significant inclusions, and the woodgrain pattern must be clearly visible without obvious imperfections such as leaks or creases. It is worth noting, however, that the presence of creases and wood grain patterns is permitted in corners and recesses. However, if the wood grain pattern appears to be ghosted or blurred, then such a finish will be considered substandard.

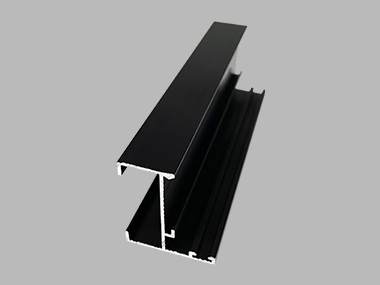

4.

Electrophoresis coating aluminium profile

In terms of coating film, uniformity and neatness are the basic requirements. The aluminium door and window profile treated with electrophoresis should not have wrinkles, cracks, bubbles, flow marks, inclusions, sticking and flaking. All these defects may affect the overall beauty and durability of the coating film. However, taking into account certain special circumstances in actual processing, the ends of the profiles are allowed to be partially filmless.