Materials used in aluminium extrusion heat sink profiles

Aluminium extrusion heat sink profiles are common material used by people to dissipate heat. It helps many electronic and electrical appliances to maintain a reasonable temperature and can run normally for a long time effectively. And heat sink profiles aluminium has good electrical conductivity, thermal conductivity, and very durable. Therefore, many electronic manufacturers will choose aluminum profiles made of heat sinks. So what are the raw materials for heat sink aluminium extrusion? What are the properties of these raw materials? Retop below to help you answer your questions.

.jpg) Heat sink copper vs aluminium

Heat sink copper vs aluminium

Aluminum and copper are common heat sink materials. Unique metal properties, so that both materials can be made into a heat sink. But the two materials have their own characteristics.

1. Aluminum alloy: Aluminum alloy is one of the most commonly used materials in the manufacture of radiators, especially 6063 and 6061 aluminum alloy. In addition to good thermal conductivity, aluminum alloy also has good plasticity. Therefore, aluminum alloy can be easily made into various shapes of radiators. At the same time, aluminum alloy is lightweight, easy to use, install and repair.

2. Copper: Copper is also a very good thermal conductivity material, often used in high-end radiators. Its thermal conductivity is better compared with aluminum alloy. However, copper is more expensive and more difficult to process.

Aluminum alloy can be used as heat sink

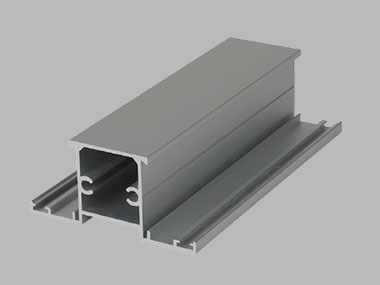

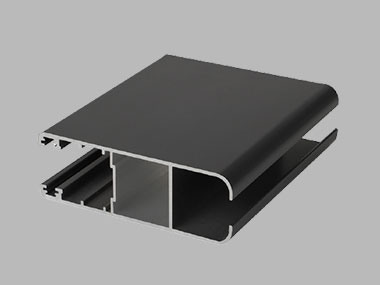

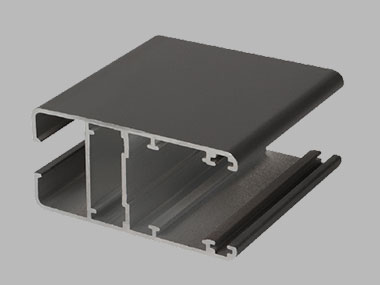

Aluminium extrusion heat sink profiles

Aluminum alloy can be used as heat sink

Aluminium extrusion heat sink profiles are generally 6000 series aluminum alloys. It generally refers to 6061, 6063 and 6060.

1. 6060 aluminum alloy

6060 aluminum alloy has high strength. Excellent corrosion and oxidation resistance. Good thermal and electrical conductivity for applications requiring efficient heat dissipation and current conduction.

2.6061

aluminum alloy

6061 aluminum alloy is more stable and is weaker in strength compared to 6060 aluminum alloy. This aluminum alloy is more stable and can be easily processed in a variety of ways. It also has excellent weldability and plating properties, and is easy to join with other metals.

3.6063 aluminum alloy

6063 aluminum alloy made radiator heat conduction performance is strong, density is small. Strength and pressure resistance are high. The price is relatively low, so it is the aluminum alloy material preferred by manufacturers in many industries.

Most common aluminium extrusion heat sink profiles

Most common aluminium extrusion heat sink profiles

The most common aluminium extrusion heat sink profiles is mainly 6063 aluminum alloy. This is because this aluminum alloy is popular for its excellent thermal conductivity, low density and good machinability.

1.6063 Its low density makes the heat sink lighter in weight, which will also make the weight of the installed electronic products reduced.

2. In addition, 6063 aluminum alloy is highly malleable. The heat sink can be manufactured into various shapes by extrusion. This can meet different heat dissipation needs.

Why is pure aluminum unsuitable for heat sinks?

Compared with aluminium alloy heat sink the pure aluminum is lack of hardness and poor cutting performance.

1. Therefore, in order to improve the hardness and machinability of aluminum. People will add some other metal elements to pure aluminum. For example, magnesium, manganese, copper, silicon, zinc and so on.

2. Pure aluminum is also not the best choice in alkaline water or high-pressure working environment. While aluminum alloy and copper are perfectly suitable for these scenarios.

Conclusion

Conclusion

In summary, 6060,6061 and 6063 can all be aluminium heat sink material. The actual choice of which aluminum alloy to use needs to be determined by your usage scenario. Choosing the right aluminium extrusion heat sink profiles and applying it in the right usage scenario can bring you better heat dissipation effect! As a professional aluminum profile manufacturer, Retop can make various shapes of heat sink profiles aluminium. If you have any needs please contact us!

.jpg)