Custom aluminum extrusions production process

Custom aluminum extrusions is the process of making aluminum profiles according to the specifications of the drawings provided by the customer. The customized aluminum profiles are usually not the common aluminum profile standard and need to be re-made with extrusion molds. The process of making this type of aluminum profile is the same as the process for common aluminum profiles. Only the detailed parameters of the aluminum profile need to be communicated with the customer before manufacturing. Generally it is necessary to make a drawing and make a new extrusion mold, and then make a sample. Mass production can be launched when the customer indicates no doubt about the samples. Below are the specific production steps:

Specific custom aluminum extrusions steps

Specific custom aluminum extrusions steps

1. Aluminum profile drawing design

When we receive the order of custom aluminum profiles. We will first design technical drawings according to the customer's drawings. Retop will use

CAD computer technology to do this. These designs help to accurately obtain the dimensions, tolerances and surface finishes described by the customer. This helps to help customers produce more accurate and structurally sound aluminum section structures.

2. Extrusion molds

Custom aluminum extrusions require extrusion molds that are not readily available from most manufacturers. Therefore, the manufacturer will start to make aluminum extrusion molds that are unique to the customer. These aluminum extrusion dies are made of high quality steel, which is the most durable and accurate material.

3. Alloy selection

Aluminum alloys are created by combining aluminum with other metal elements. However, different types of alloys have different characteristics and are used in different applications. For example, sturdiness, ductility, corrosion resistance, thermal conductivity and so on. For example,

heat sinks aluminum profile will generally use it 6063 aluminum alloy. Because it has good thermal conductivity. Different application scenarios will use different types of alloys. We will recommend the corresponding aluminum alloy according to the customer's specific application.

.jpg)

4.Heating

In the whole extrusion process, temperature control is crucial, which directly affects the forming quality and productivity of custom aluminum extrusions. Aluminum profile manufacturers will first preheat the die and aluminum profile. The temperatures are 500 and 400-500 degrees Celsius respectively. This preheating treatment allows the aluminum to retain enough heat when it comes into contact with the die during the pressing process, reducing heat loss and ensuring that the aluminum is extruded smoothly and in the desired form. During all this time, the manufacturer keeps a close eye on the temperature changes and makes fine adjustments according to the actual situation, resulting in a high quality product.

5. Extrusion

When the billet has reached a level of ductility suitable for extrusion, the manufacturer removes it from the furnace. The billet is then mechanically positioned precisely on the extruder so that it can be smoothly extruded through the die opening under the impetus of a powerful punch.

6. Hardening

The custom made aluminium profiles are shaped to match the cross-section of the mold as it passes through the die opening. At the exit end, a puller precisely guides the aluminum profile to an exit table, which usually consists of a fan or water bath. Its function is to harden the extrusion. Different types of alloys require different quenching times.

7. Straightening

After the quenching is completed. The staff will transfer the customized aluminum profiles to the hopping table for further cooling and straightening. This subsequent further processing of the aluminum profile paves the way and improves the mechanical properties.

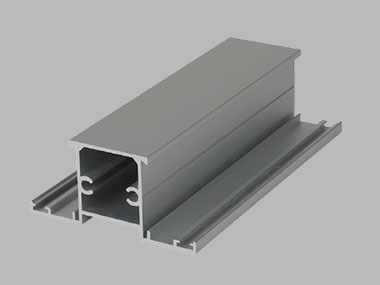

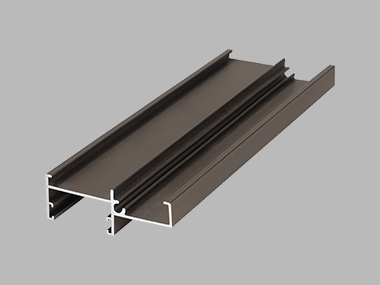

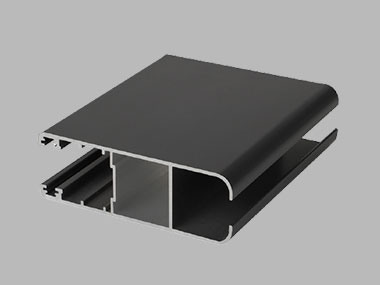

Deep processing of customized aluminium frame profile

Retop will further process customized aluminium profile according to the specific needs of the customer. The following are the deep processing treatment that can be will have:

1. Cutting

Aluminum profile suppliers will cut the aluminum profiles into certain lengths according to customers' needs.

2.Punching

The manufacturer will punch holes and other special features in the tempered profile to help assemble the structure and improve functionality. In addition to these, aluminum profile manufacturers can also bend, uncoil and weld aluminum profile products.

3. Surface treatment

Aluminum profiles with surface treatment will further improve performance. It is also more aesthetically pleasing. Retop can provide a variety of surface treatment, such as powder coating, anodizing, wood grain transfer, electrophoresis and other surface treatment. Various colors are also added to the surface treatment. This helps to harmonize with the architectural style that the customer needs to decorate.

Quality inspection of custom aluminum extrusions

Quality inspection of custom aluminum extrusions

After all the manufacturing and further processing work is done, the aluminum profile manufacturer conducts quality tests on the final custom aluminum extrusions product. These tests include tensile strength test, hardness test, impact absorption test and corrosion resistance test. After testing in these areas, customers will clear the characteristics of these custom profile extrusion profiles.

This is the entire process of producing custom aluminum extrusions profiles. If you have any demand for customizing aluminum profiles, please contact us anytime!

.jpg)

.jpg)