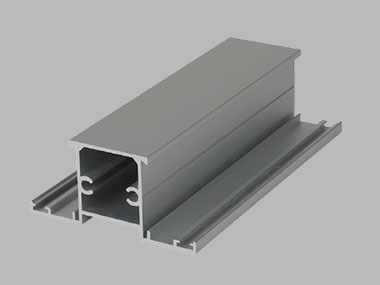

Extrusion profile aluminium are a material widely used for indoor and outdoor decoration and building structures, featuring light weight, good thermal conductivity, and high plasticity. Its production process includes multiple handling and processing steps to form aluminum profiles of various shapes and sizes. Many users are interested in the production process of extrusion profile aluminium. The following is Retop's production process of aluminum profiles.

What does the extrusion profile aluminium process include?

The general aluminum profile processing flow is extrusion, drawing, surface treatment, deep processing, packaging and so on. The following content is mainly a brief introduction to extrusion and surface treatment. These two parts are important links in the aluminum profile production process. You can use them as a reference to have a more in-depth understanding of the production of aluminum profiles.

Hot extrusion of aluminum profiles

Hot extrusion is a common aluminum profile processing flow. In the extrusion process, aluminum is pushed into the extruder and extruded from the die orifice through high pressure to form the desired cross-section shape, and various complex shapes of aluminium alloy profiles can be produced through the extrusion process.

Steps of aluminum profile hot extrusion

1. Material Preparation: Select appropriate aluminum alloy material and carry out necessary pretreatment, such as cleaning and removing oxidized skin.

2. Heating: Heat the aluminum material to an appropriate temperature to make it plastic and easy to extrude.

3. Extrusion: The preheated aluminum is placed in the extruder and extruded through the die orifice by high pressure to form the desired cross-section shape.

4. Cooling: The extruded aluminum profile passes through a cooling table, where it is rapidly cooled down by water cooling to enhance the mechanical properties.

5. Cutting and trimming: The cooled and cured extrusion profile aluminium is cut to the required length and trimmed to remove burrs and irregular edges.

Cold extrusion of extrusion profile aluminium

Cold extrusion of extrusion profile aluminium

Cold extrusion is an extrusion process carried out at room temperature, by applying pressure to the cooled aluminum, it will be extruded out of the die to form the desired shape of the aluminum profile. Cold extrusion is commonly used in the production of special requirements of aluminum profiles, such as tubes, filaments and so on.

Cold extrusion of aluminum extrusion steps

1. Material preparation: select the appropriate aluminum alloy and carry out the necessary pre-treatment.

2. Heating (optional): Heat the aluminum material to improve its plasticity as needed.

3. Cold extrusion: The aluminium alloy profile is put into the cold extruder and high pressure is applied at room temperature to form the desired shape through the die.

4. Cutting and trimming: The cold extruded aluminum profile is cut and trimmed to meet the requirements and obtain a flat surface.

Stretching of aluminium alloy profile

Stretching of aluminium alloy profile

The drawing process of aluminum profiles is used to produce drawn aluminum profiles. The process involves heating the aluminum to the proper temperature and then applying a force in a stretching machine to stretch it along its length, thereby changing the cross-section shape and size.

Steps in aluminum profile stretching

1. Material Preparation: Select the appropriate aluminum alloy material and carry out the necessary pre-treatment, such as cleaning and removing the oxide skin.

2. Heating: Heat the aluminum material to an appropriate temperature so that it has sufficient plasticity.

3. Stretching: Put the preheated aluminum into the stretching machine and apply force to make it stretch along the length direction to change the cross-section shape and size.

4. Cooling and curing: After stretching, the aluminum profile enters the cooling table for rapid cooling, and then undergoes curing treatment in the curing oven to increase the hardness and strength.

5. Cutting and trimming: The cured aluminum profiles are cut and trimmed according to the requirements to remove irregular edges and burrs.

Surface treatment of aluminum sections

1. Anodizing

Surface treatment of aluminum sections

1. Anodizing

Oxidation is a surface treatment process to improve the corrosion resistance and surface hardness of extrusion profile aluminium by forming an oxide film on the surface.

Steps of anodic oxidation

1. Cleaning: Clean the extrusion profile aluminium to remove the impurities and dirt on the surface.

2. Anodizing: Put the aluminum profile into the electrolysis tank as an anode, and apply current in the electrolyte to form an oxide film.

3. Dyeing (optional): Make the oxide film have different colors by treating in dyeing solution.

4. Sealing: Seal the oxide film to improve its weathering and corrosion resistance.

2. Electrophoretic coating

2. Electrophoretic coating

Electrophoretic coating is a commonly used surface coating process, by immersing aluminum profiles in electrophoretic coating and using electric field to even out the coating.

Steps of electrophoretic coating:

1. Adhere to the surface of aluminum profiles to form a protective film and improve the weather resistance and appearance quality of aluminum profiles.

2. Prepare the coating: choose appropriate electrophoretic coating, stir and mix.

3. Pre-treatment: Clean and surface treat the aluminum profile to provide good adhesion.

4.

Electrophoresis: Extrusion profile aluminium are suspended in an electrophoresis tank so that the particles in the coating solution are charged and attach to the aluminum surface to form a uniform coating through the action of the electric field.

5. Curing: The coating is cured by baking or curing oven to ensure the hardness and durability of the coating.

Aluminum profiles from Retop

Aluminum profiles from Retop

Retop has 18 extrusion presses which can produce aluminum profiles from 500UST to 4000UST. We also have 2 horizontal and 1 vertical powder coating lines. We have a complete aluminum profile production process. In addition to making standard extrusion profile aluminium, we can also customize unique aluminum profiles. For example, we can customize the structure of aluminum profiles, the color of aluminum profiles, and the surface treatment of aluminum profiles. Our advanced production technology allows us to produce aluminum profiles that are needed in different fields. Our aluminum profiles include

architectural aluminum profiles, decorative aluminum profiles and industrial aluminum profiles. You are welcome to inquire anytime!